First:

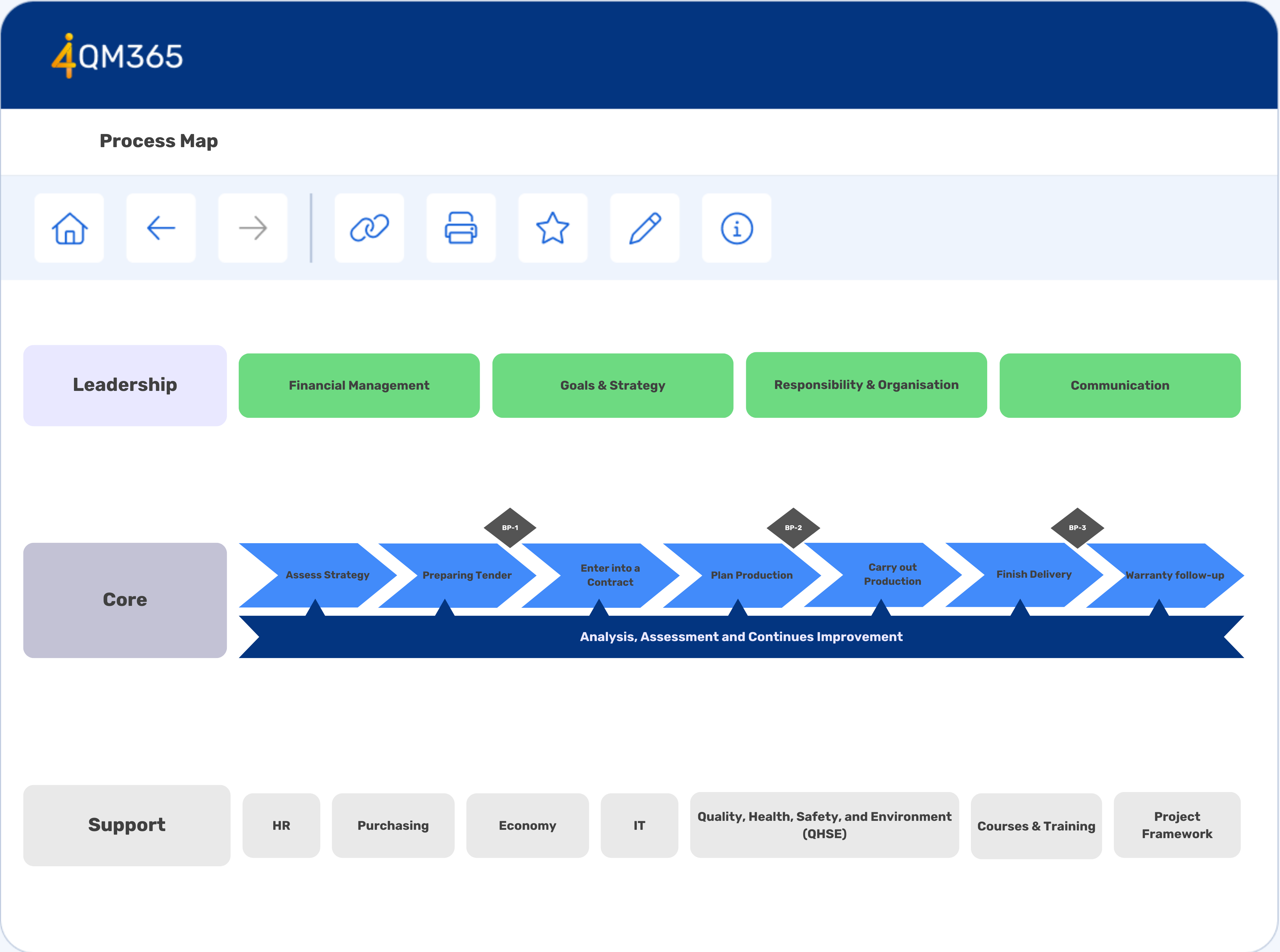

Why Process Mapping?

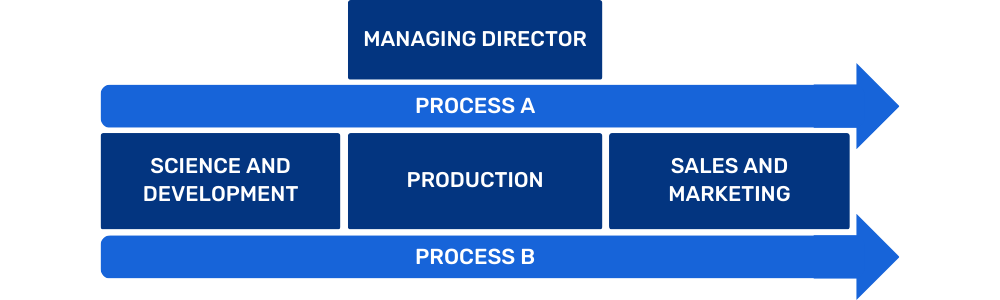

An organisational chart is all about hierarchy—it shows who reports to whom but says nothing about what’s done, how it’s done, or who it’s for.

A process map, on the other hand, tells the real story. It connects customers, products, and workflows, showing how work actually gets done across departments. It’s like switching from a static snapshot to a dynamic, behind-the-scenes tour of your organisation.

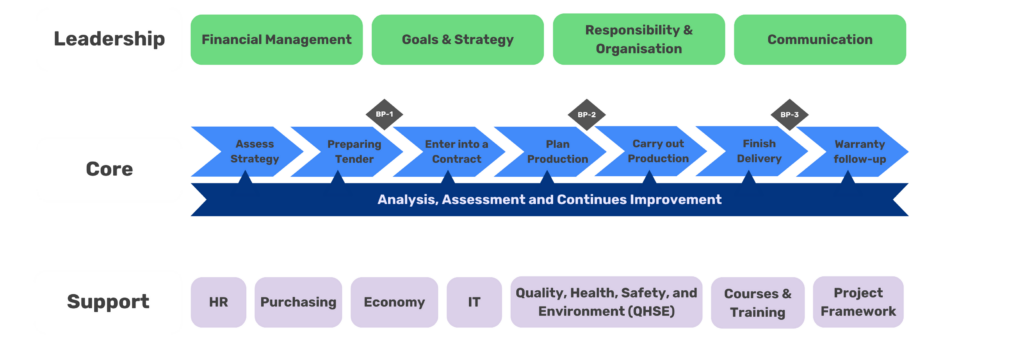

Process catagories:

1. Leadership

2. Core

3. Support

Process catagories:

1. Leadership Process

The purpose of management processes is to set strategy and chart the course for the organisation. In some cases, it can be difficult to determine what is support and what are core processes. Here, a good assessment will provide the right answer.

2. Core Process

When working with quality, core processes should have a customer focus. When deciding which processes are core, you start with customer needs and end with customer satisfaction. They follow the willingness to pay. These are the processes that ensure earnings directly and represent the development and delivery of your products and services.

3. Support Process

Supporting processes are those processes whose purpose is to help the main processes create satisfied customers. They do not create value directly, but consume resources to support the main processes. Examples include invoicing, IT support and HR.

Process Mapping in Practice

There are several ways to map processes. One method we have good experience with in 4human QM365 is to gather a small number of knowledgeable people from all areas of the organisation. If it’s a large organisation, you can divide it into several sub-collections using the same methodology

Building a process map

Although the rich functionality enables advanced process maps, we recommend making these maps as simple as possible. Remember that they should provide valuable information not only to the certifier or quality manager, but perhaps first and foremost to each individual employee.

So the process map needs to be easy to understand and easy to use. Our software has powerful functions for linking all relevant information to the individual process, such as

ISO-Certified Process Mapping Solution

Clarity – Get a clear, structured overview of your processes.

Efficiency – Streamline workflows to save time and boost productivity.

Compliance – Ensure ISO-certified, audit-ready processes.

Optimization – Identify bottlenecks and improve performance.

Competitive Edge – Work smarter and stay ahead of competitors.