A good process map makes it easy for employees to get an overview of the business. But how should you go about drawing a good process map?

ISO 9001 encourages us to work process-based. The challenge for most businesses is to create clear process maps that all employees can easily recognize. It is also important to be able to easily see what one’s area of responsibility is, and how this area of responsibility is connected to the rest of the business.

Why process maps

First, one must understand the difference between a classic organization chart and a process chart.

An organization chart is a vertical and functional description of the business. An organizational chart does not say anything about what we do, who we do it for or how we do it.

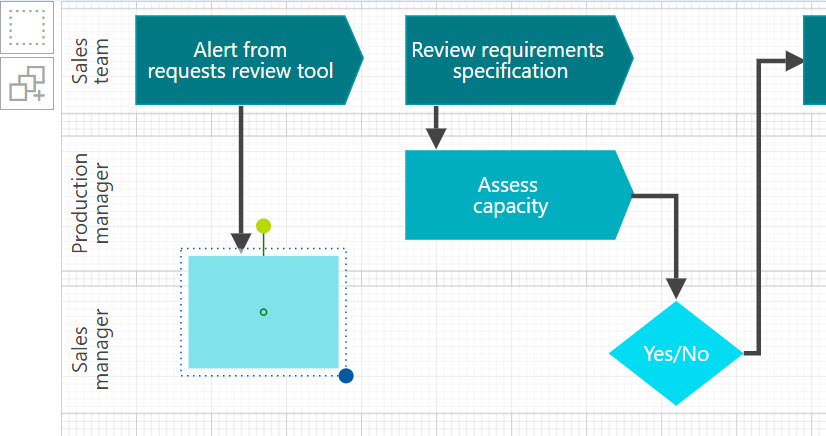

A process map, on the other hand, shows the organization as a system where the customer, the product and the workflow are connected. It becomes possible to see how the work is carried out through processes that cross functional boundaries and departments.

ISO 9001 is very specific here and requires that processes be identified and managed to meet customer expectations. Managing according to processes is, therefore, necessary if you want to hold an ISO certification and are in any case to recommend.

Establishing a process map helps the employee to see the entire production line instead of only focusing on maximizing their goals internally in their department.

Process categories

Process map showing an example of core process management processes and support processes Processes are most often divided into three categories: Core processes, support processes and management processes.

Core process

When working with quality, core processes must have a customer focus. When deciding which processes are core, you start with customer needs and end with customer satisfaction. These are the processes that ensure earnings directly and represent the development and delivery of their products and services.

Support process

Support processes are those processes whose purpose is to help the main processes to create satisfied customers. They do not create value directly but consume resources to support the main processes. Examples of this could be invoicing, IT support and HR.

Management process

Management processes are intended to lay down a strategy and set the course for the business. In some cases, it can be difficult to determine what is support and what are core processes. Here, a good assessment will give the right answer.

Process mapping in practice

There are several ways to map processes. A methodology we have good experience with within QM365 is to bring together a few knowledgeable people from all areas of the company. If it is an extensive business, it can be divided into several sub-collections but with the same methodology.

1. Quiet brainstorming

Everyone sits around the same table. The question everyone gets is: What is going on in our company? What am I doing? Everyone writes down keywords, quietly, without cooperation.

2. Notes up on the wall

All notes must go up on the wall or a board.

Silent sorting: Grouping notes that are similar to each other and belong together (the affinity method). This is done without discussing or talking.

3. Silent sorting

Try to sort the notes in a natural order. Patches that have to do with management should be at the top, support should be at the bottom, and a large block in the middle is the core.

4. Name each group of notes

Strive to use verb + noun. For example, “Remove paint” and “Provide an offer” instead of “Paint removal” and “Offer delivery”. In this way, you get an active, instead of a passive, process map.

The advantage of this methodology is that you get a lot of information in a very short time. Discussions are often time-consuming and this is avoided to a large extent when using this method described above. You create involvement and ownership. Everyone gets to contribute to the process map – it is not drawn up by the QA Manager who uses his words and terms and sets up what he thinks is relevant.

If you work in a business that has a production map, work map or flow chart, you must consider working something differently for this part to ensure that the flow is correct.

To build a process map

A good process map is an important foundation in building up a simple and comprehensible management system – no matter which management standard you are going to implement. After you have agreed together on what your process map looks like, you have a good basis for building up your graphic process map.

In our management system, it is easy to draw up their processes. There are features to design each process box as you like when it comes to size, colour and desired icon. You can also choose font design and graphic elements such as arrows and lines between the boxes.

Although the rich functionality enables advanced process maps, we recommend making these maps as simple as possible. Remember that they must provide valuable information not only to the certifier or quality manager but perhaps primarily to each employee. Then the process map must be easy to understand and easy to use.

Process maps features

Our software has powerful functions to connect all relevant information to the individual process, such as:

- All information on a sub-process is available directly from the process map in QM365 Manage.

- Process description – documentation visible directly on the map.

- Documents – management documents, templates and registrations

- Activities – additional documentation in text boxes

- Risks

- Laws and requirements

- Goal

- Links to relevant websites and tools

In addition, the process map can sort by positions and roles so that a user sees all information that is relevant to them. The process map can also handle different businesses and large departments where certain processes can be shared if desired.

In QM365, we have extensive experience in helping our customers create simple and good process maps!

Do you need help with process mapping?

Feel free to get in touch for a chat about how we can assist your work with process mapping. We can help you with software to draw up and communicate your process maps – and we have experienced advisors who can help you with your work on mapping your processes.